Products

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Cartridge heater

Cartridge heater is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080), High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form, that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms – high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.industrial heater

Cartridge heaters

Resistance heating wire

NiCr 80/20 wire

sheath

stainless steel 304,321,316, Incoloy 800, Incoloy 840

Maximum temperature

800 degree Celsius

Wattage Tolerance

+5%, -10%

Resistance tolerance

+10%, -5%

Voltages available

380V,240V, 220V,110V,36V,24V or 12V

Length tolerance

±1 mm

Diameter tolerance

-0.02mm

Standard Cold Zone

5-10mm

Insulation resistance (cold)

≥ 500 MΩ

Maximum leakage current (cold)

≤ 0.5 mA

-

Carbide KMT Internal Grinder Spindle

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide KMT Internal Grinder Spindle

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide KMT Internal Grinder Spindle

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

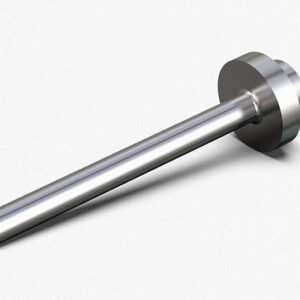

Studer Internal Grinder Spindle

4596

Part Name:Internal Grinder Spindle

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:Studer Internal Grinder or Toyo Internal Grinder

Major Parameter:

- Critical Dimensional Accuracy:±005

- WorkingSpeed:100,000rpm

- Run Out:002;

- Minimum Internal Thread:M2;

- Smooth Finish:Ra0.05-0.10。

-

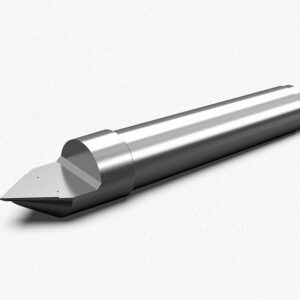

Studer Carbide-Tipped Center

7857

Part Name:Carbide-Tipped Center

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:Studer Internal Grinder or Toyo Internal Grinder

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Posalux V Collet

0452

Part Name:Posalux V Collet

Texture:Cemented Carbide

Corollary Equipment:Posalux EDM Machine

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Smooth Finish:Ra0.05-0.10。

-

Posalux Flat Collet

0126

Part Name:Posalux Flat Collet

Texture:Cemented Carbide or Ceramic

Corollary Equipment:Posalux EDM Machine

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Smooth Finish:Ra0.05-0.10。

-

Nissin Honing rod

7867

Part Name:Nissin Honing rod

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:Nissin Honing Machine

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

KMT Internal Grinder Spindle

9635

Part Name:Internal Grinder Spindle

Texture:Cemented Carbide

Corollary Equipment:KMT Internal Grinder or UVA Internal Grinder

Major Parameter:

- Critical Dimensional Accuracy:±005

- WorkingSpeed:100,000rpm

- Run Out:002;

- Minimum Internal Thread:M2;

- Smooth Finish:Ra0.05-0.10。

-

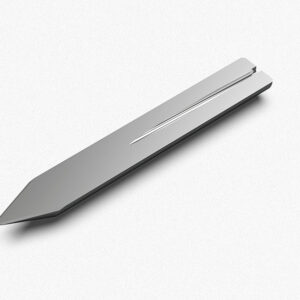

IC Stamping Knife

0205

Part Name:IC Stamping Knife

Texture:Cemented Carbide

Corollary Equipment:IC Made

Major Parameter:

- Critical Dimensional Accuracy:±002

- Planeness:002;

- Parallelism Tolerance:002;

- Smooth Finish:Ra0.05-0.10。

-

IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

IC Injection Nozzle

Part Name:IC Injection Nozzle

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

CMT Carbide-Tipped Tailstock Center

7485

Part Name:Carbide-Tipped Tailstock Center

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:CMT Cylindrical Grinder

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

CMT Carbide-Tipped Drive Center

4545

Part Name:Carbide-Tipped Drive Center

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:CMT Cylindrical Grinder

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Posalux V Collet

0452

Part Name:Posalux V Collet

Texture:Cemented Carbide

Corollary Equipment:Posalux EDM Machine

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Smooth Finish:Ra0.05-0.10。

-

Nissin Honing rod

7867

Part Name:Nissin Honing rod

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:Nissin Honing Machine

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

KMT Internal Grinder Spindle

9635

Part Name:Internal Grinder Spindle

Texture:Cemented Carbide

Corollary Equipment:KMT Internal Grinder or UVA Internal Grinder

Major Parameter:

- Critical Dimensional Accuracy:±005

- WorkingSpeed:100,000rpm

- Run Out:002;

- Minimum Internal Thread:M2;

- Smooth Finish:Ra0.05-0.10。

-

IC Stamping Knife

0205

Part Name:IC Stamping Knife

Texture:Cemented Carbide

Corollary Equipment:IC Made

Major Parameter:

- Critical Dimensional Accuracy:±002

- Planeness:002;

- Parallelism Tolerance:002;

- Smooth Finish:Ra0.05-0.10。

-

IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

IC Injection Nozzle

Part Name:IC Injection Nozzle

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

CMT Carbide-Tipped Tailstock Center

7485

Part Name:Carbide-Tipped Tailstock Center

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:CMT Cylindrical Grinder

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

CMT Carbide-Tipped Drive Center

4545

Part Name:Carbide-Tipped Drive Center

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:CMT Cylindrical Grinder

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Studer Internal Grinder Spindle

4596

Part Name:Internal Grinder Spindle

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:Studer Internal Grinder or Toyo Internal Grinder

Major Parameter:

- Critical Dimensional Accuracy:±005

- WorkingSpeed:100,000rpm

- Run Out:002;

- Minimum Internal Thread:M2;

- Smooth Finish:Ra0.05-0.10。

-

Studer Carbide-Tipped Center

7857

Part Name:Carbide-Tipped Center

Texture:Cemented Carbide or SKD11+ Cemented Carbide

Corollary Equipment:Studer Internal Grinder or Toyo Internal Grinder

Major Parameter:

- Critical Dimensional Accuracy:±002

- Run Out:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Posalux Flat Collet

0126

Part Name:Posalux Flat Collet

Texture:Cemented Carbide or Ceramic

Corollary Equipment:Posalux EDM Machine

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Smooth Finish:Ra0.05-0.10。

-

Carbide KMT Internal Grinder Spindle

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide KMT Internal Grinder Spindle

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide KMT Internal Grinder Spindle

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Carbide IC Injection Pushrod

Part Name:IC Injection Pushrod

Texture:Cemented Carbide

Corollary Equipment:IC Injection Mould

Major Parameter:

- Critical Dimensional Accuracy:±002

- Cylindricity:002;

- Out Of Roundness:0008-0.0010;

- Smooth Finish:Ra0.05-0.10。

-

Bahmueller Internal Grinder Spindle

7862

Part Name:Internal Grinder Spindle

Texture:Cemented Carbide

Corollary Equipment:Bahmueller Internal Grinder or GMN Spindle

Major Parameter:

- Critical Dimensional Accuracy:±005

- WorkingSpeed:100,000rpm

- Run Out:002;

- Minimum Internal Thread:M2;

- Smooth Finish:Ra0.05-0.10。

About Us

Xiamen Deciwell Precision Machine Co., Ltd was established as a professional manufacturer of high-quality customized tungsten carbide forming tools, including carbide bushings, cutting rings, carbide plates, carbide wear parts, carbide nozzles, Carbide Cutting Punches, carbide water jet nozzles, tool steel & carbide soldered bushings & punches with tight tolerance. We understand 100% accuracy, outstanding service, and rapid delivery save our customers time.

News

Cooperation with Cummins about the Carbide tools

In 2016, Cooperation with Cummins about the Carbide tools

Carbide nozzles use and advantages

Carbide nozzles are mainly used for cooling drill teeth, flushing mud and cleaning downhole cuttings when working with tools such as PDC bits and roller cones for oil and gas drilling. Cemented carbide has a series of excellent properties such [...]

Tungsten Uses: Cemented Carbide, Alloys and More

Tungsten, also known as wolfram, is a shiny, silvery-white metal with low reactivity and the highest melting point of all metals. It is also one of the heaviest metals with a density of 19.25 grams per cubic centimeter. Tungsten is mined all over the [...]